Detaje të shpejta

Gjendja: E re

Fuqia e vlerësuar: 7.5kw

Dimensioni (L*P*H): 2100*3200*1600

Pesha: 1000KG

Certifikimi: CE ISO

Garancia: 1 vit

Shërbimi pas shitjes i ofruar: Inxhinierë të disponueshëm për makineri shërbimi jashtë shtetit

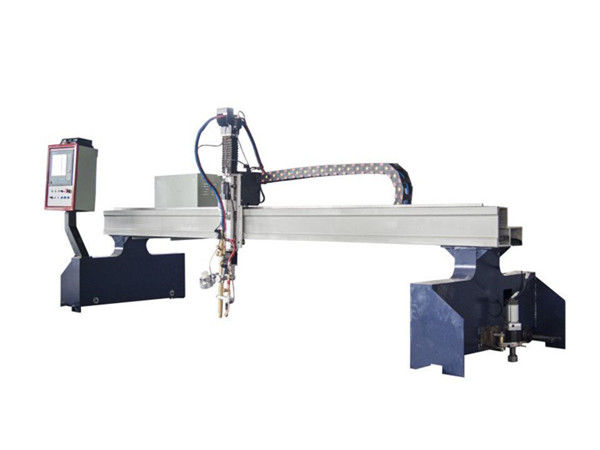

Emri i produktit: makineri prerëse metalike me pantograf cnc me dorezë të vogël/prerës plazma cnc

Ngjyra: e personalizueshme

Materiali i prerjes: Alumini i çelikut të çelikut të pandryshkshëm

Aplikimi: Prerja e fletëve të metalit

Ekrani: LCD

Shpejtësia e prerjes: 0-8000mm / min

Trashësia e prerjes: 0-200 mm

Furnizimi me plazma: Jiangsu Jiusheng

Softueri: STARCAM

Sistemi CNC: F2300B

Pjesët kryesore

1.Treja përdorni udhëzues linear.

2. Beam miraton strukturën e tipit të kutisë dhe kornizën e portave. Pas saldimit, përdorimi i trajtimit për lehtësimin e stresit të dridhjeve për të lehtësuar stresin e mbetur dhe për ta bërë atë të mos bëhet deformim.

3. Sistemi i transmetimit mekanik miraton të gjithë kushinetat e topit me precizion dhe saktësinë e procesit të standardit kombëtar të nivelit 7, rrjetëzimi i saktë i ingranazheve dhe rafteve.

4. Sistemi i makinës miraton reduktuesin planetar nga bashkëpunimi kino-gjerman. Gabimi i tij në hyrje dhe në dalje është vetëm 16 hark. Në strukturën e transmisionit horizontal dhe vertikal të marsheve rritet pajisja automatike e hendekut të kompensimit e cila mund të bëjë që struktura e transmisionit të zbatojë rendin sipas sistemit CNC.

5. Rrezi kryesor i lëvizjes: Pajisja shtrënguese gjatësore e hekurudhës miraton strukturën automatike të orientimit, jo pajisjen e çuditshme të shtrëngimit të rrotave. Ajo mbështetet në forcën e pranverës së strukturës udhëzuese automatike dhe e bën atë të ecë të qëndrueshme në dy drejtime dhe nuk do të duket fenomen i ngushtë dhe i lirshëm.

6. Të gjitha pjesët e strukturave të vidave dhe çelikut përdorin të gjitha proceset e veshjes së zezë ose kromi.

Parametri teknik

NO | artikull | Vlera | njësi |

1 | Distanca udhëzuese tërthore | 3000 | mm |

2 | Gjerësia efektive e prerjes | 2500 | mm |

3 | Gjatësia e shiritit udhëzues gjatësor | 8000 | mm |

4 | Gjatësia efektive e prerjes | 6000 | mm |

5 | Trashësia e prerjes plazmatike | Çeliku i karbonit është ≤6 | mm |

6 | Pishtari lart e poshtë lartësisë | ≤150 | mm |

7 | Shpejtësia e prerjes | 50-3500 | mm / min |

8 | Sistemi i makinës | Motori me hap | |

9 | Program kompjuterik fole | STARCAM |

Features

1. Ngurtësi e mirë, saktësi e lartë. VSR për të përballuar stresin.

2. Struktura e salduar me pllaka çeliku, shuarja e temperaturës së lartë, siguron jetën e makinerive.

3. Makinë vertikale dhe horizontale.

4. Disku i hapës së brendshme (Sistemi i makinës së importuar për opsional).

5. Sistemi i programimit automatik, i cili është mostër dhe funksionon lehtë.

6. Kontrolli CNC.

7. Softueri i foleve CAM.